Inverter for sync control system VF66AD/VF66PD

These are advanced function models equipped with the sync control function and high-precision drawing control function of the continually evolving VF66SV.

Features/functionality

- VF66AD: Absolute sync control

- VF66PD: Incremental sync control

- Example application to sectional drive system

We have commercialized absolute sync control and delivered countless commercial rotary press drive systems. Absolute sync performs rotation commands and motor rotation feedback via numeric data. To achieve a resolution of 33,554,432 Digit/r, SHPC-175-Z is used for the rotation command module and an absolute encoder for the motor.

| Absolute rotation command module |

|---|

| SHPC-175-Z |

| Rotation position commands and rotation speed commands are sent via our proprietary sync communication |

| For high-precision draw and sync control |

| Minimizes delay between sections when accelerating/decelerating |

| RS422 |

External view of module

The VF66PD is the successor to the VF64SDS inverter. It applies incremental sync control to the VF64SDS inverter, and we have already delivered countless numbers to our customers. VF66PD’s sync control uses a PG emulator module that generates A, B, Z phases in commands. It uses SHPC-172-Z as a PG emulator module and an incremental encoder for a motor, thereby achieving 76,800 P/r.

| PG emulator module |

|---|

| SHPC-172-Z |

| Generates and outputs rotation position commands using A, B, Z, and phase signals |

| For high-precision draw and sync control |

| Minimal delay between sections when accelerating/decelerating |

| RS422 or optic fiber |

External view of module

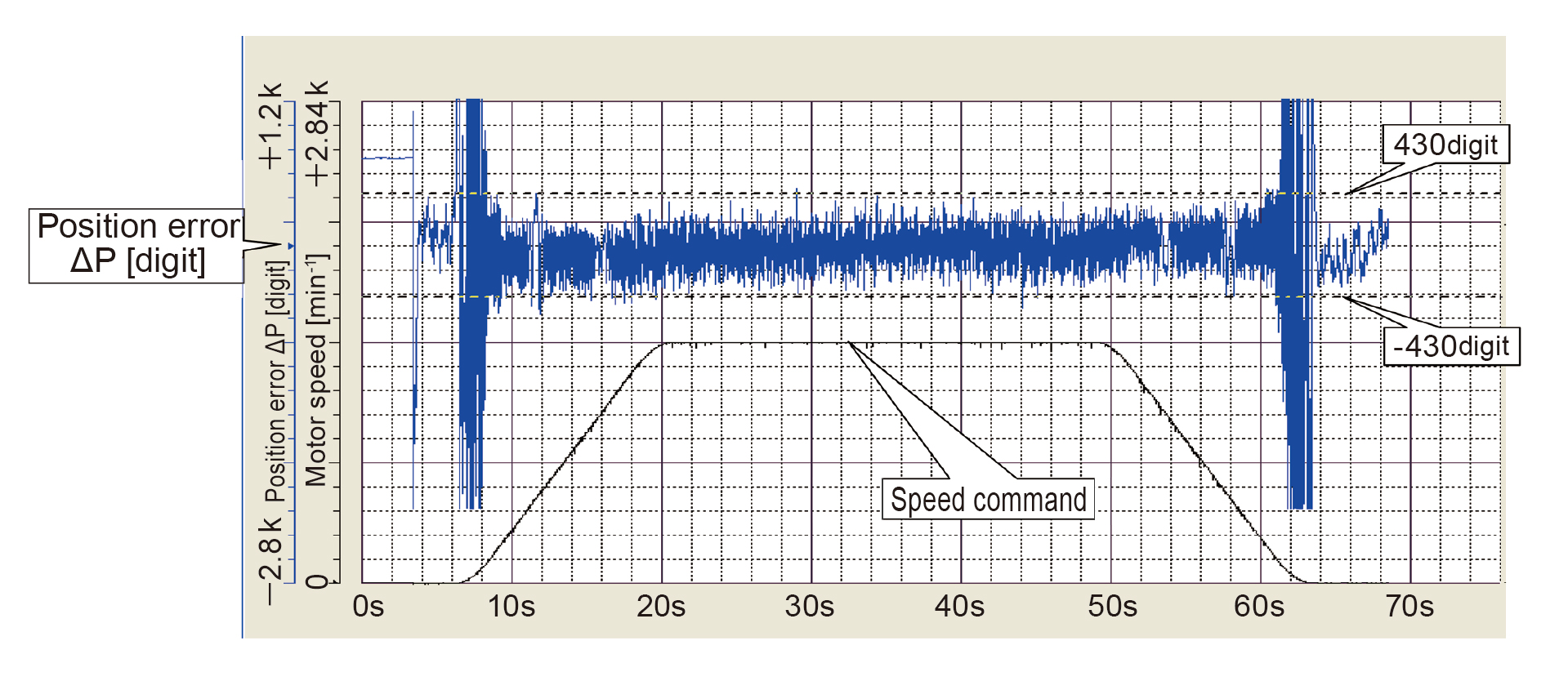

This is an example of applying VF66AD to a shaftless rotary press. It achieves a speed control precision of ±0.001% and delivers sectional drive at a precision never before possible. The bottom step represents the speed command for the motor, and the top waveform represents the changes in rotation position error ΔP.

Rotation position error in sync control

Specifications

| Control method | Vector control with speed sensor |

|---|---|

| Capacity | 200 V class: 5.5 to 180 kW 400 V class: 2.2 to 1,000 kW |

| Rated power | 200~220 V 380~460 V±10% 50/60 Hz±5% |

| Output frequency | 0.1~400 Hz |

| Overload capacity | 150% for 1 minute 200% for 3 seconds (when at low temperature, 75 kW or more is 150% max) |

| Network | OPCN-1 |

| Input signal | Analog ±10 V (2CH) 8 multifunction inputs |

| Output signal | Analog ±10 V (2CH) 3 multifunction outputs |